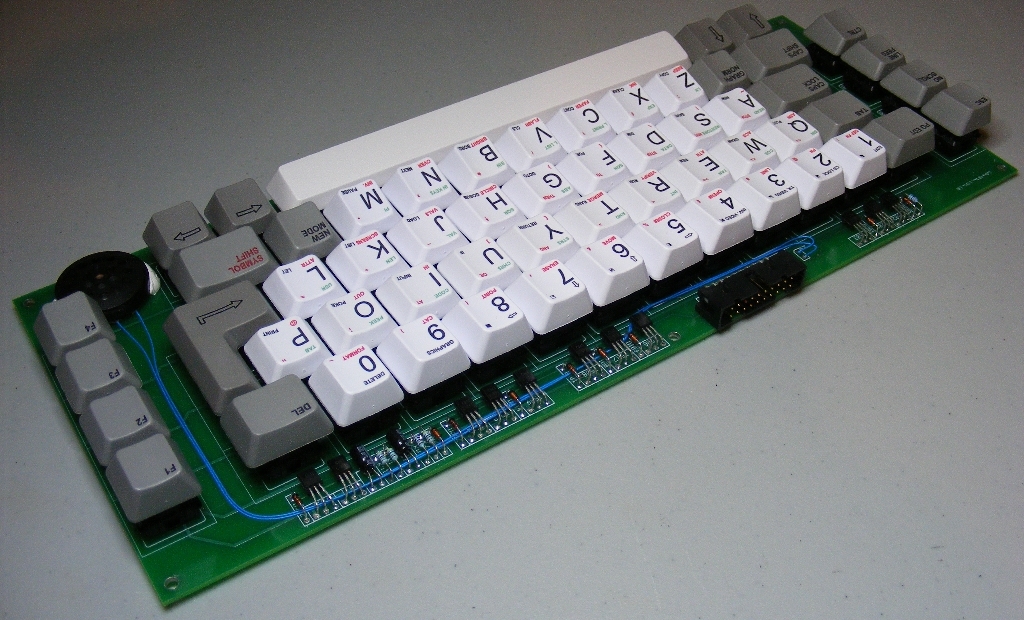

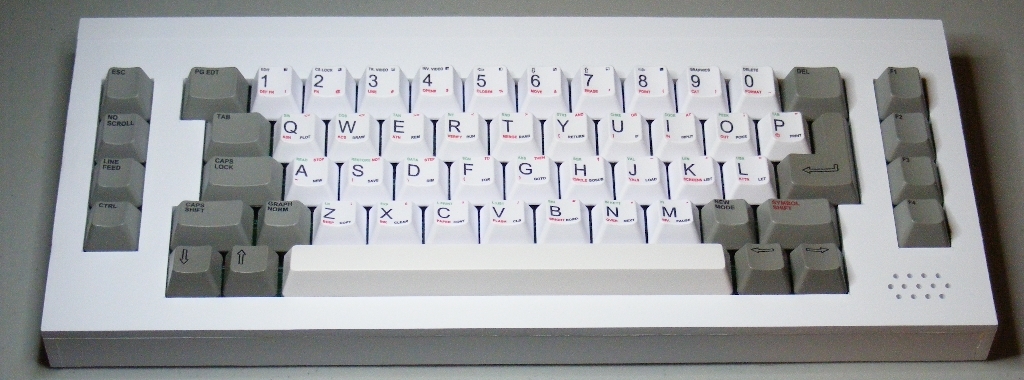

| Successfully built | Keyboard - Version 1.0 |

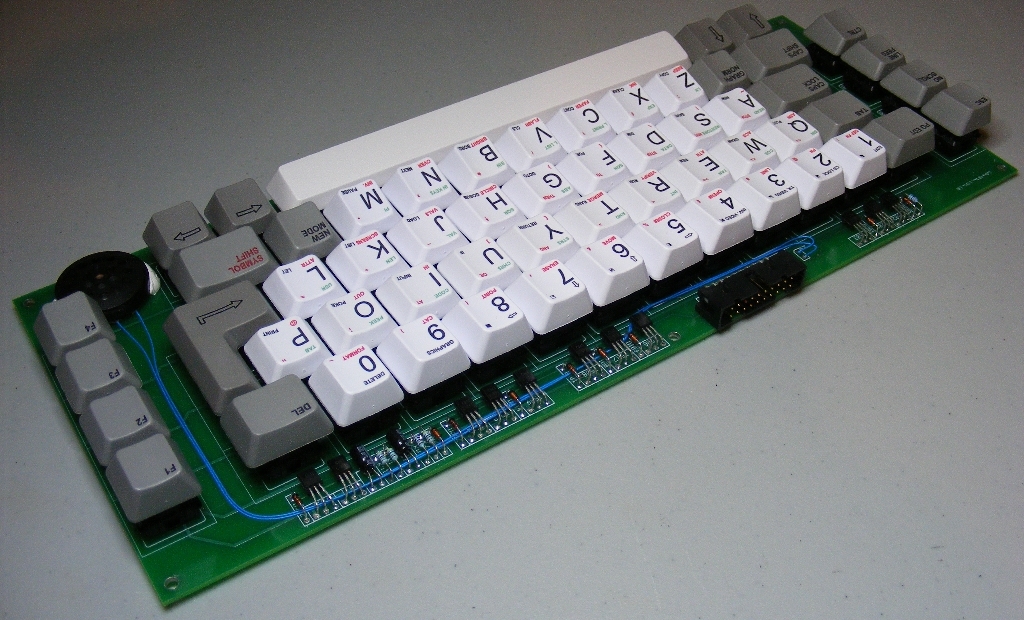

| PG EDT, DEL, TAB | 1.25 x 1 |

| CAPS LOCK, CAPS SHIFT, SYMBOL SHIFT | 1.5 x 1 |

| SPACE | 8 x 1 |

| ENTER | 0.75 x 2 x 1.5 x 1 |

| rest of the keys | 1 x 1 |

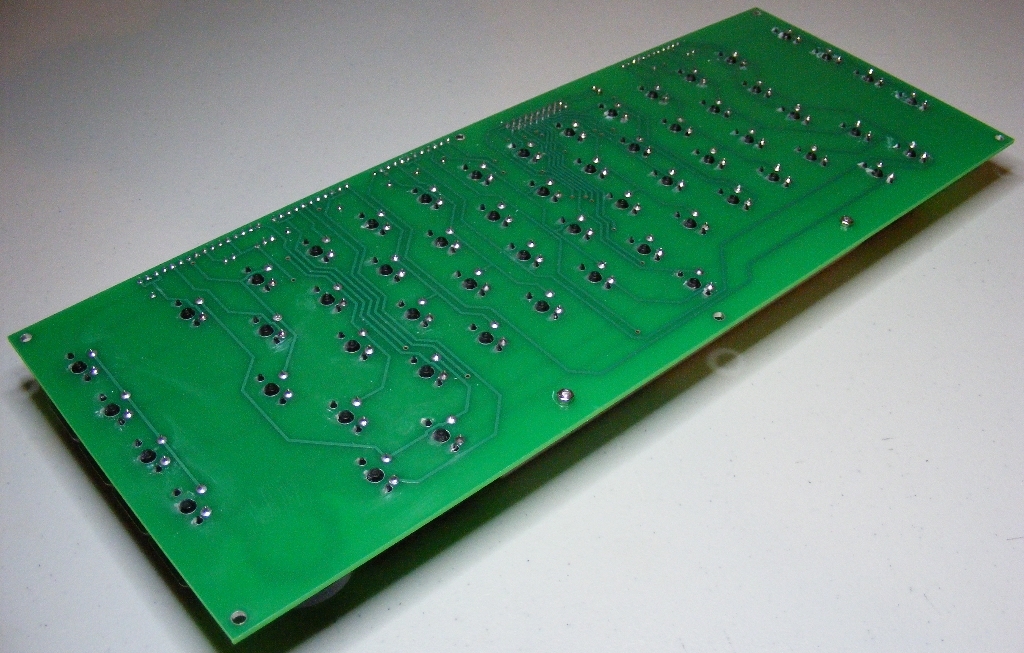

Keyboard schematic - v.1.0 | |

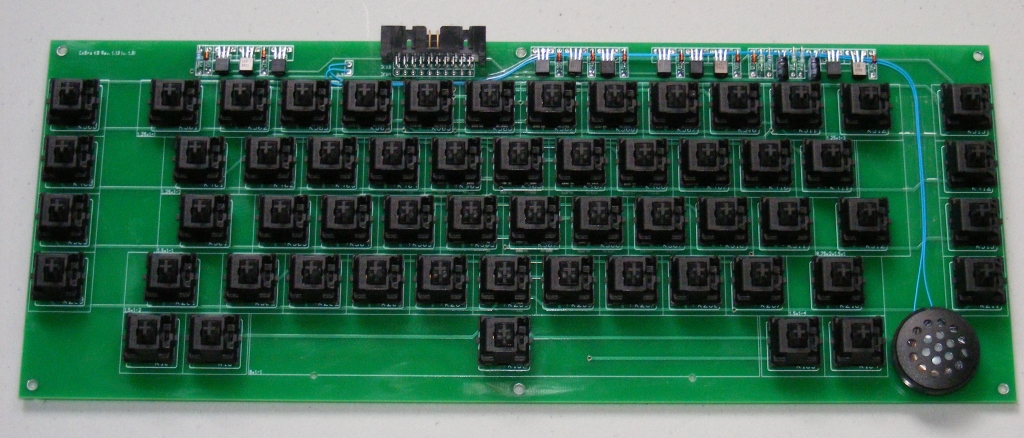

NOTE:The original version of the keyboard was using a 1 x 20 pin connector to the mainboard. On the mainboard, the connector had 2 x 10 pins. So using a 20-wire flat cable, the mainboard end of the cable could be attached to the connector in a civilized manner, whereas the keyboard end had to be spread away like a broom in order to cover a width twice as big. That's why I designed the layout for v.1.0 using a 2 x 10 pin connector, to achieve a decent manner of connection to the mainboard through a 20-wire flat cable having 2 x 10 pin connectors at each end. |

|

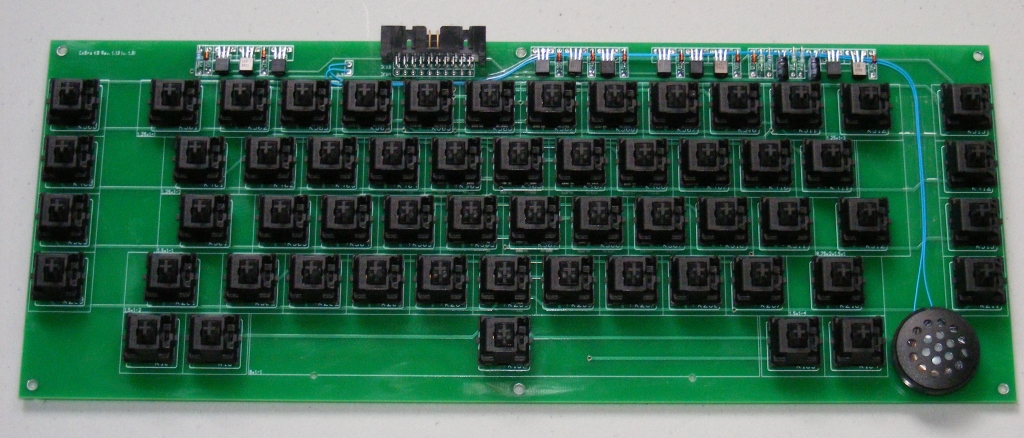

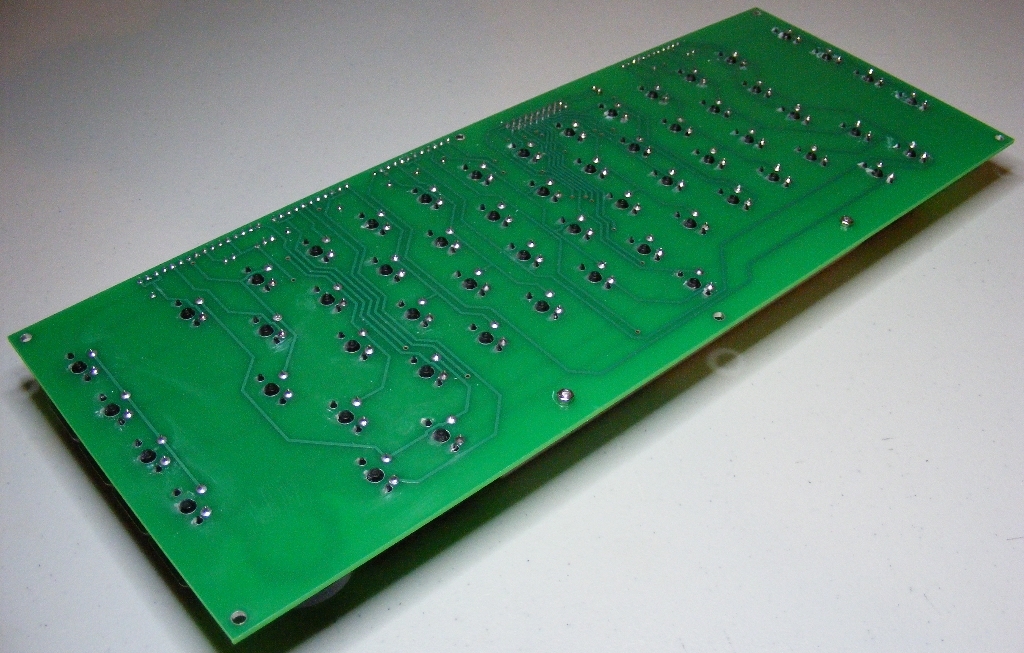

Circuit board layout - v.1.0 |

| I designed the keyboard using MX Series switches manufactured by Cherry Electrical. The keycaps have been ordered from a specialized keyboard manufacturer. |

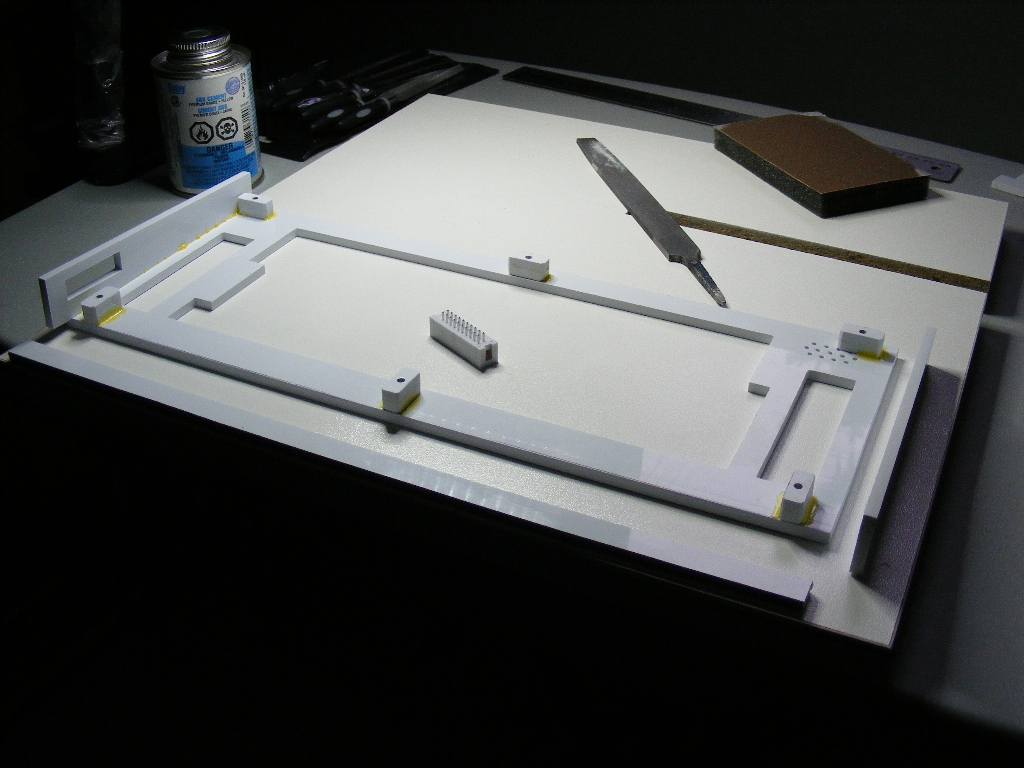

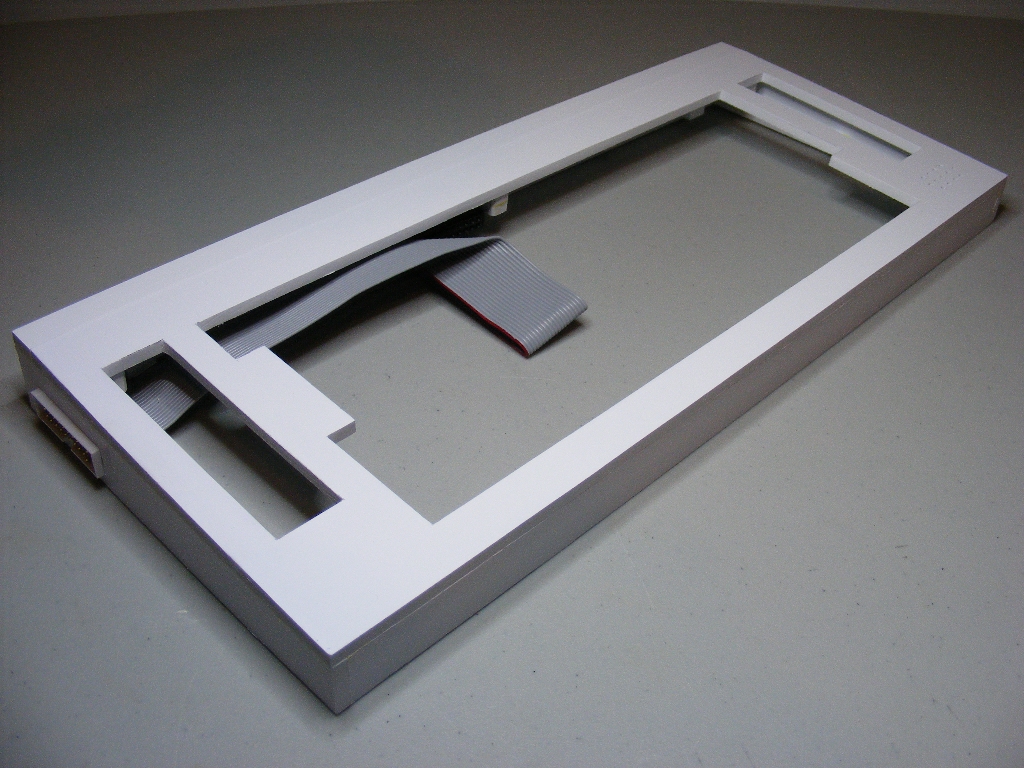

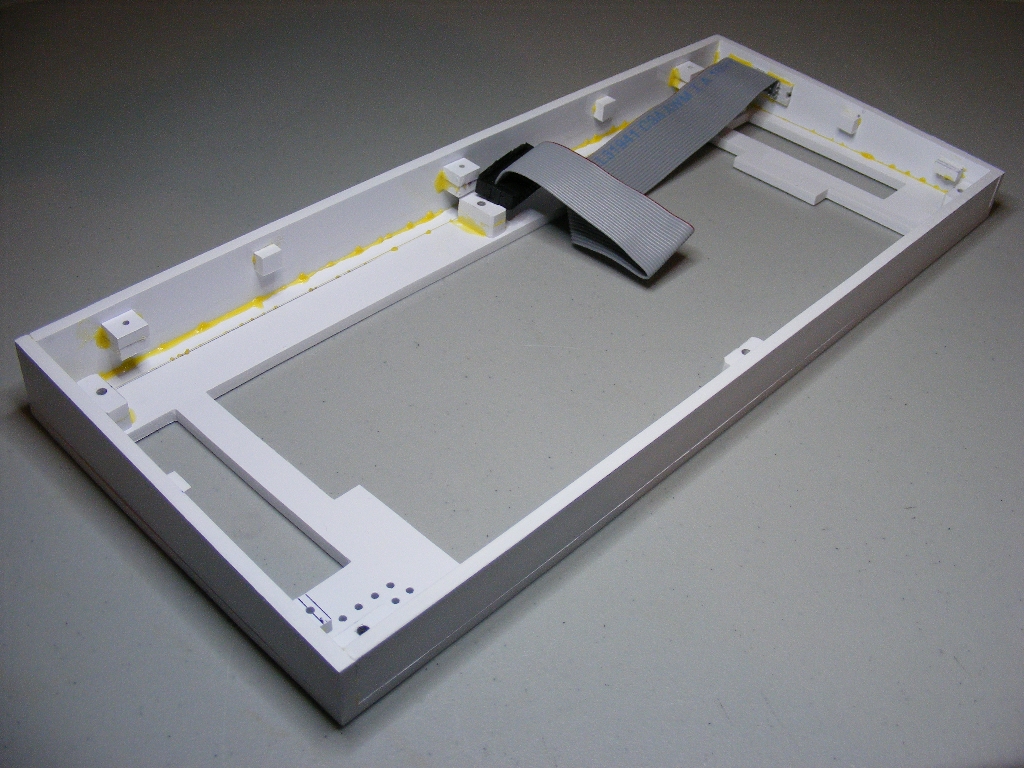

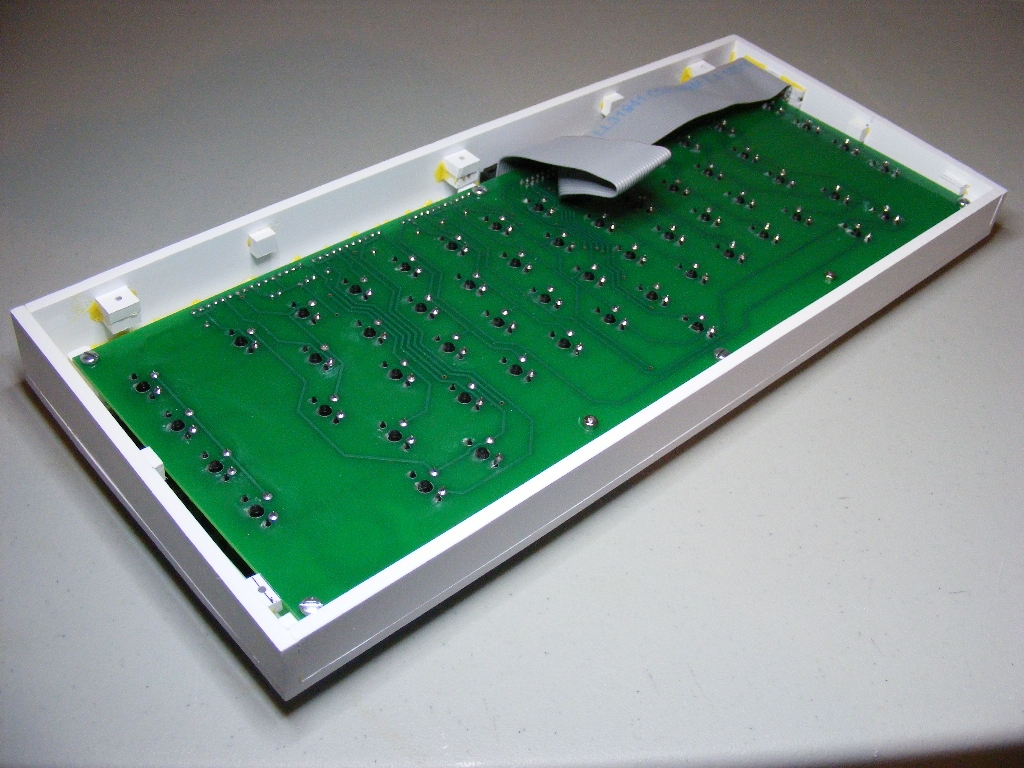

Actual construction:

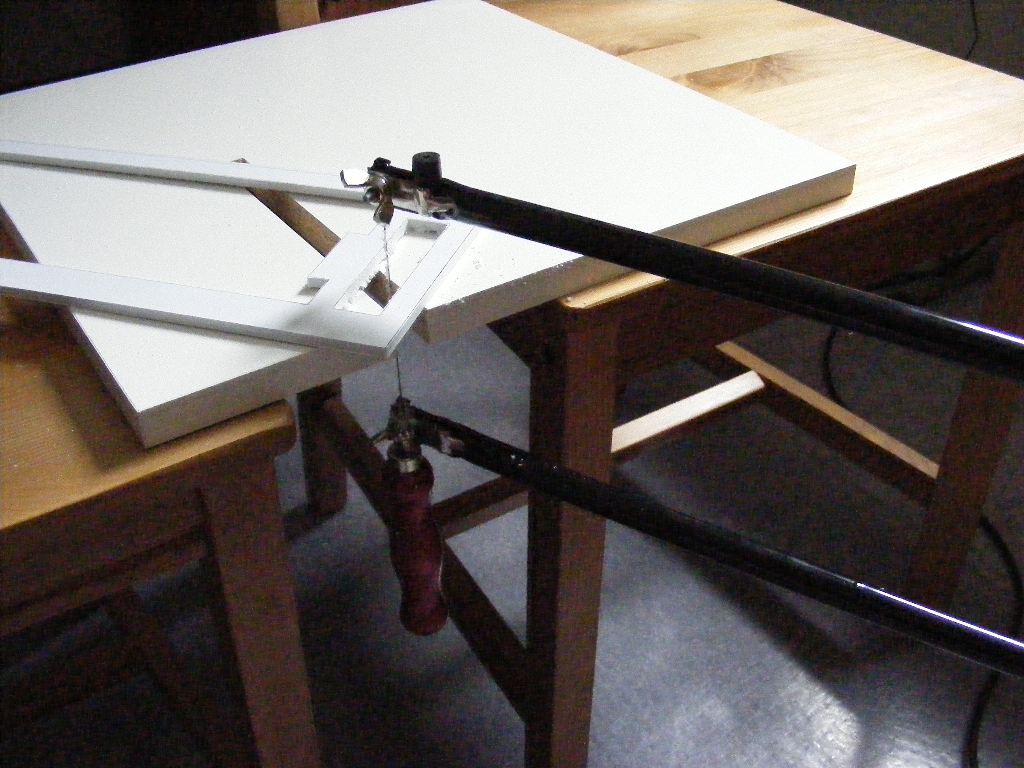

When assembling it, the biggest trouble was the leveling system for the SPACE bar, consisting of a piece of thick steel wire, which I had to bend to some very exact dimensions, and of two very little pieces of thin sheet metal cut, drilled and bent to 90° which guide the thick piece of steel wire at ends (see the third image below). These two little brackets are fastened with M2 screws and nuts to the keyboard circuit board, and then secured in place with some glue.  |

|

|

|

|

|

|

|

|

|

|

|

|

|